Invented by HOSSAIN; Mohammad Kamal, KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Surface-enhanced Raman scattering (SERS) has long promised to make chemical detection much more sensitive, selective, and reliable. But making SERS live up to its potential has always been tricky. Now, a recent patent application proposes a new way to make, map, and use SERS substrates—using gold nanoparticles on glass, special dyes, and near-field scanning optical microscopy (NSOM). Let’s take a deep dive into what this patent covers and why it could be so important for the future of chemical and biological sensing.

Background and Market Context

Let’s start simple. Raman spectroscopy is like a fingerprinting tool for molecules. You shine a laser on something, and some of the light bounces back differently, letting you see what the material is made of. But the signal is usually weak. That’s where SERS comes in. If you put your target molecules on a special surface—often made of gold or silver nanoparticles—the signal gets much stronger. This means you can detect tinier amounts of stuff, or see details you missed before.

Why does this matter? There’s a huge need for tools that can spot tiny traces of chemicals, drugs, toxins, or even viruses and bacteria. For example, drug companies want to check for the smallest impurities in medicine. Food safety labs want to find traces of harmful chemicals. Doctors want quick tests for disease markers in blood or urine. SERS offers all this, but only if the surfaces (called “substrates”) are reliable, easy to make, and work the same way every time.

But here’s the problem. SERS substrates are hard to make perfectly. The magic happens in tiny places called “hotspots,” where the electric field is strongest between nanoparticles. These hotspots can be as small as a few nanometers—way smaller than what normal microscopes can see. If you don’t know where the hotspots are, or if they change from spot to spot, your test results will be all over the place. This makes it hard for SERS to move from the lab to the real world.

In the market, companies are pushing for better SERS substrates. Some use random rough metal surfaces, some use carefully arranged nanoparticle arrays, and some even print nanoparticles. But few can promise the same results every time, or say exactly where the hotspots are. This means that if you want to trust SERS for real-world testing—say, in a hospital, factory, or airport—you need a way to map, store, and use hotspot patterns with high precision and repeatability.

That’s where this patent application steps in. It gives a process where each glass slide is carefully coated with gold nanoparticles, then treated so the spots where hotspots appear can be mapped, stored, and recalled later. The key? Using near-field scanning optical microscopy (NSOM)—a tool that can “see” at the nanoscale—to find and map the hotspots for each slide. The information is kept in a database, so later on, you can use the same slide and know exactly where to look for strong signals. This could make SERS much more reliable and useful in the field.

Scientific Rationale and Prior Art

To understand why this invention matters, it helps to know how SERS and NSOM work, and what’s been tried before.

Raman spectroscopy, as we said, is about shining light and measuring how the color (wavelength) changes when it bounces off molecules. The changes are tiny, but they tell you what kind of bonds and atoms are present. SERS takes this a step further. If you put your molecules next to a rough metal surface or nanoparticles (usually gold or silver), the signal gets much stronger—sometimes a million times stronger or more.

Why does this happen? It’s mostly because of a physical effect called the “electromagnetic enhancement mechanism.” When light hits metal nanoparticles, it makes the electrons in the metal wiggle together (a “plasmon”). If two nanoparticles are close together, the spot in between them—the “interstitial”—can have an electric field that’s way stronger than anywhere else. Molecules sitting in these hotspots get their Raman signal boosted hugely.

But, finding and controlling these hotspots is hard. They’re tiny—often just a few nanometers across. Most regular microscopes can’t see them, and regular SERS substrates have hotspots in random places. Sometimes you get lucky and your molecule lands in a hotspot, but most of the time you don’t. This leads to inconsistent results.

Past work has tried to fix this. Some scientists use electron microscopes to see where nanoparticles are. Some try to make “ordered” arrays where the hotspots should be in the same place every time. Others use special chemicals to stick nanoparticles together in controlled clusters. But, even with these tricks, it’s hard to know exactly where the best hotspots are on each slide, and how strong they are.

This is where near-field scanning optical microscopy (NSOM) comes in. NSOM uses a very sharp probe—much sharper than the wavelength of light—to scan over a surface. This lets you “see” optical features as small as 10 nanometers. NSOM can map out where light is strongest on a SERS substrate, showing exactly where hotspots are. Some research groups have used NSOM to look at SERS substrates, but these studies often focus on understanding how SERS works, not on building practical, reusable systems.

Another key idea is using special dyes, like rhodamine 6G, as “test molecules.” These dyes have strong Raman signals. By putting the dye on a SERS substrate and scanning with NSOM, you can quickly find and map out the hotspots—because the dye will light up wherever the field is strongest.

But until now, there hasn’t been a method that puts all this together: making slides with carefully controlled gold nanoparticles, coating them with a dye, mapping all the hotspots with NSOM, storing the exact positions and properties of each hotspot in a database, and then using this info to identify unknown chemicals later on. This is what makes the new patent application different from the past.

Invention Description and Key Innovations

Now, let’s break down what this patent application actually claims, and why it’s new.

At its core, the invention is a method and system for making, mapping, and using SERS substrates that are more reliable and traceable than before. Here’s how it works, step by step:

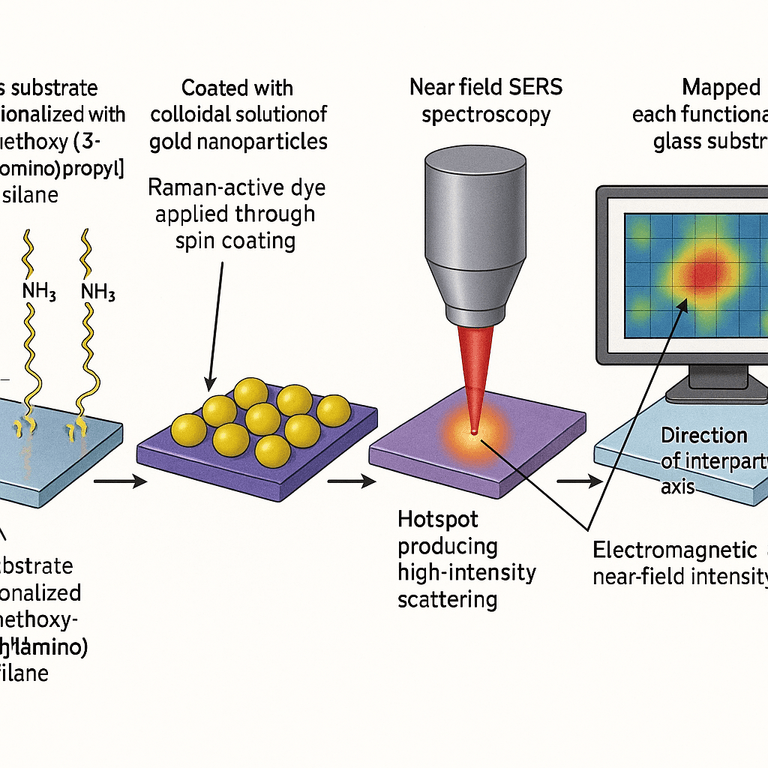

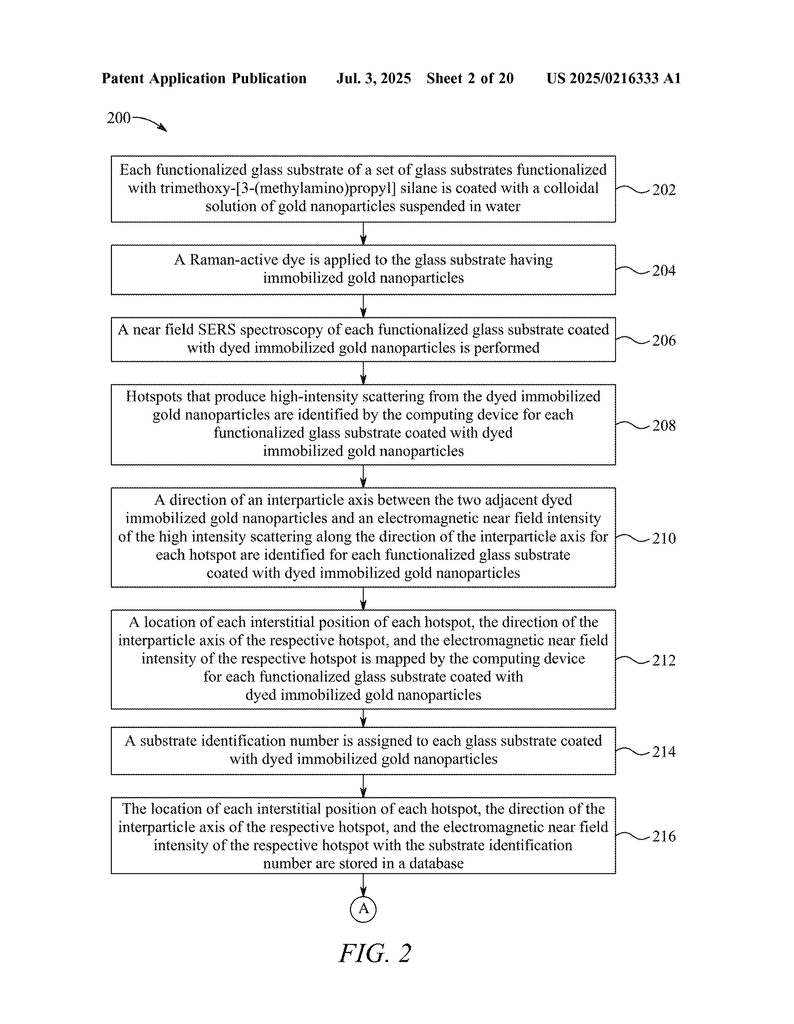

First, you start with a set of glass slides. Each slide is treated with a chemical called trimethoxy-[3-(methylamino)propyl] silane. This treatment makes the glass sticky for gold nanoparticles. Then, a solution of gold nanoparticles (each about 100 nanometers across) is added, and the nanoparticles stick firmly to the surface. Because of the chemical treatment, the nanoparticles are immobilized in place—they won’t move around during tests.

Next, a Raman-active dye (like rhodamine 6G) is applied. This is often done by spin coating, which spreads a thin, even layer of dye across the slide. The dye molecules stick to the gold nanoparticles.

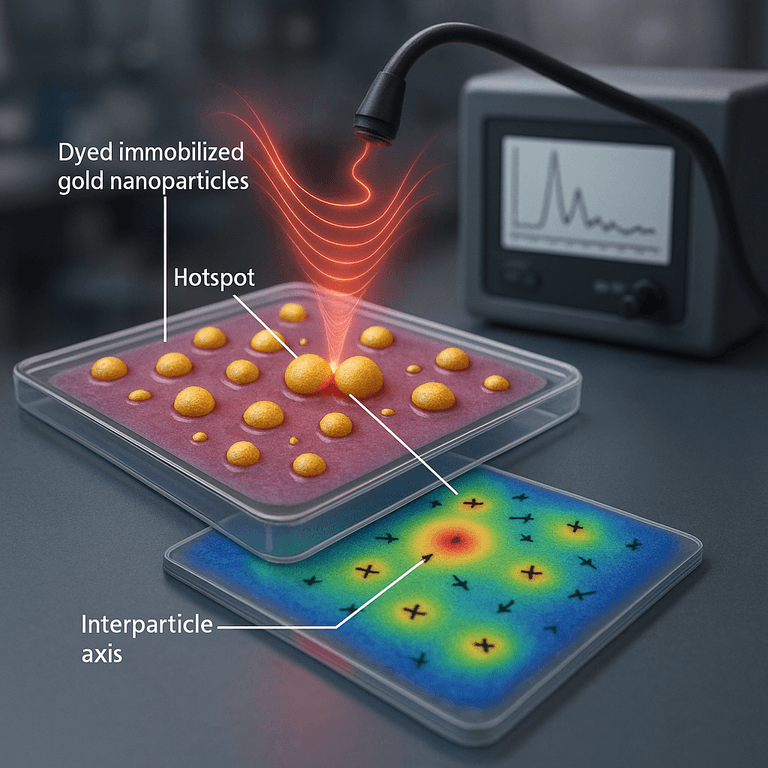

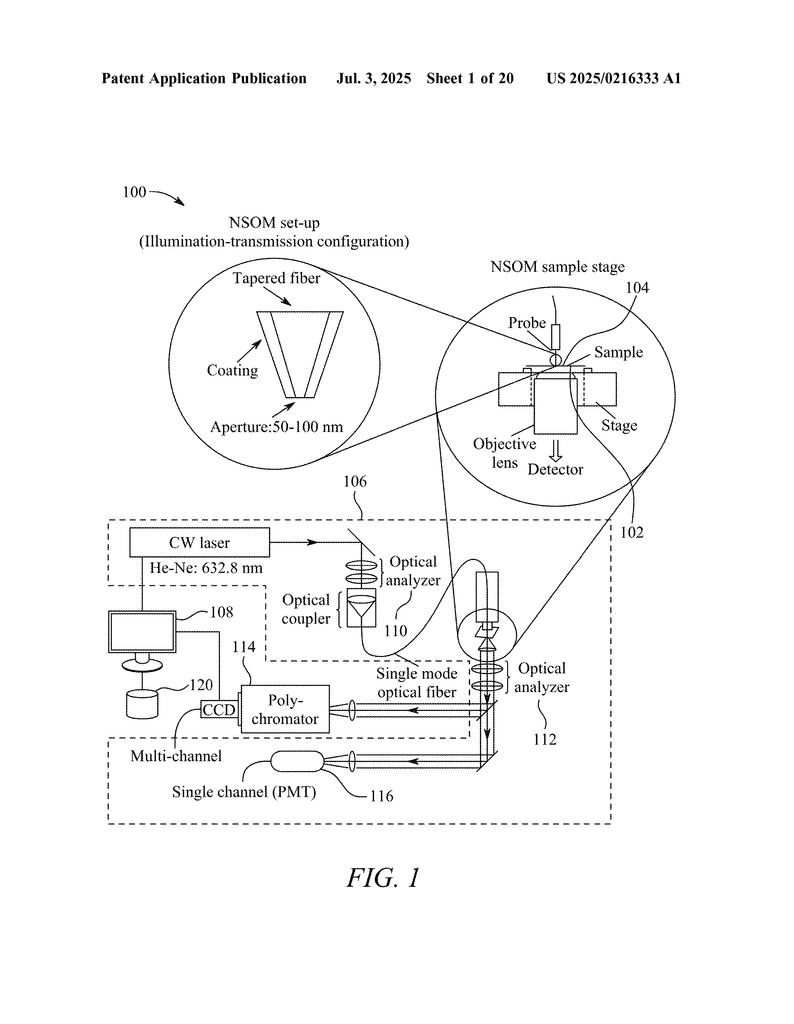

Now comes the key part: using an aperture NSOM (a-NSOM) to scan the slide. The NSOM probe is very sharp and can “feel” both the shape of the surface (topography) and the strength of the light fields (optical intensity) at each point. As the probe scans, it shines a tiny spot of laser light onto the slide and collects the Raman signal from the dye. Wherever the signal is strongest, that’s a hotspot—that is, a place between two nanoparticles where the electric field is highest.

For each hotspot, the system records three key pieces of information: the exact location on the slide, the direction of the “interparticle axis” (the line between the two nanoparticles making the hotspot), and the strength of the electromagnetic field (how bright the Raman signal is). This data is mapped and stored in a digital database, along with an ID number for that specific slide.

Later, if you want to use the slide for a real test, you retrieve its hotspot map from the database. You can then coat the slide with your unknown sample—the target analyte. Because you know exactly where the best hotspots are, you can use the NSOM again (with the laser polarized in the right direction) to look at each hotspot and collect the SERS signal. The computer compares the new signals to a library of known SERS spectra, and tells you what molecules are present in the sample.

There are several clever details in the invention:

– Using the silane chemical to fix the gold nanoparticles in place, making sure the hotspots don’t change location from test to test.

– Coating with dye by spin coating, which helps get a very even, thin layer—important for consistent signals.

– Using the NSOM not just for imaging, but also for mapping precise electromagnetic hotspots at the nanoscale, and keeping this info in a searchable digital database.

– Making sure the polarization of the laser is matched to the direction of the hotspot axis, which maximizes the SERS signal.

– Allowing re-use and targeted testing—once a slide is mapped, you can use it many times, always knowing where to look for the strongest signals.

The claims also cover using different dyes, picking the right dye for the type of molecule you want to test, and even using a gold-coated NSOM tip for even stronger “tip enhancement” effects.

All this adds up to a SERS system that is much more controlled, reliable, and repeatable than those in the past. Instead of guessing where the hotspots are, or hoping your molecule lands in the right place, you know exactly where to measure—and can compare results over time or between different labs. This could be a game-changer for anyone who relies on SERS for sensitive chemical or biological detection.

Conclusion

This patent application brings together several important advances in SERS technology. By combining precise nanoparticle placement, careful dye coating, high-resolution NSOM mapping, and digital hotspot tracking, it creates a SERS substrate that is not just more sensitive, but also much more reliable and easy to use. For scientists and companies working in diagnostics, food safety, environmental testing, or chemical analysis, this could help SERS finally deliver on its early promises. Reliable hotspot mapping and data storage make it much easier to get consistent, trusted results—moving SERS from the research lab to real-world applications.

If you’re working in any field where detecting tiny amounts of chemicals or biomolecules is important, this invention could be worth watching. By making every SERS substrate “smart”—with its own mapped and stored hotspot data—the technology offers a new standard for chemical sensing. It’s a step forward for both science and industry, and could help unlock the full power of surface-enhanced Raman scattering in the years ahead.

Click here https://ppubs.uspto.gov/pubwebapp/ and search 20250216333.