Invented by Carsten Frings, Christophe Cros, Airbus Operations SAS, Airbus SAS

Traditionally, aircraft were moved on the ground using tow tractors or tugs. These vehicles were manually operated and required skilled personnel to maneuver the aircraft safely. However, with the advent of technology, new methods have emerged that offer improved efficiency and reduced human error.

One of the most notable advancements in this market is the introduction of autonomous ground vehicles (AGVs). These vehicles are equipped with advanced sensors and artificial intelligence capabilities, allowing them to navigate the airport environment and move aircraft without human intervention. AGVs offer several advantages over traditional methods, including increased efficiency, reduced operational costs, and improved safety.

AGVs are designed to handle various types and sizes of aircraft, from small regional jets to large commercial airliners. They can be programmed to follow specific routes and schedules, ensuring timely and precise movement of aircraft. Additionally, AGVs can communicate with other airport systems, such as air traffic control and ground handling services, to optimize operations and minimize delays.

Another method that has gained popularity in recent years is the use of electric towbarless tugs. These tugs are specifically designed to move aircraft without the need for a towbar, making the process faster and more efficient. Electric tugs are powered by rechargeable batteries, eliminating the need for fossil fuels and reducing emissions. They also offer improved maneuverability and control, making them ideal for congested airport environments.

The market for these ground transportation methods is expected to witness significant growth in the coming years. The increasing demand for air travel, coupled with the need for improved efficiency and safety, is driving the adoption of advanced ground transportation solutions. Airports around the world are investing in these technologies to enhance their operations and provide a seamless travel experience for passengers.

Furthermore, the COVID-19 pandemic has highlighted the importance of contactless operations and reduced human interaction. Autonomous ground vehicles and electric tugs offer a solution to minimize physical contact and reduce the risk of virus transmission. As airports strive to implement health and safety measures, these technologies are becoming even more relevant and essential.

In conclusion, the market for methods of moving an aircraft on the ground is witnessing significant advancements and growth. Autonomous ground vehicles and electric tugs are revolutionizing the way aircraft are transported, offering increased efficiency, reduced costs, and improved safety. As the aviation industry continues to evolve, these technologies will play a crucial role in ensuring the smooth operation of airports and the overall success of air travel.

The Airbus Operations SAS, Airbus SAS invention works as follows

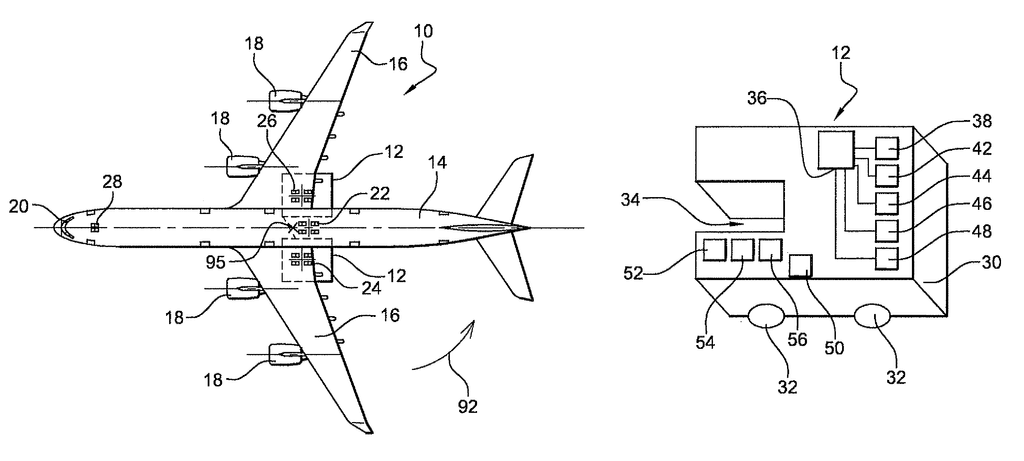

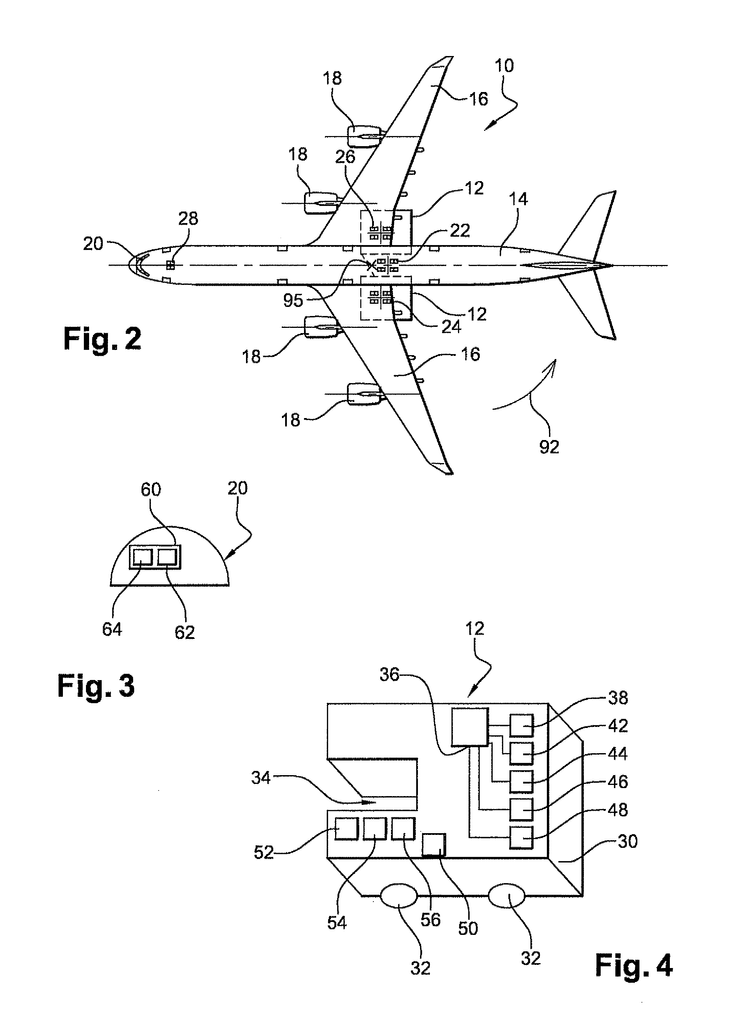

The invention relates also to an appliance (12), which implements the method according the invention. It can communicate with another identical appliance to transmit or receive at least one datum related to a position or movement of one appliance.

Background for Method of moving an aircraft on the ground

An aircraft often needs to reverse in order to leave its parking area. This movement is not usually possible by the aircraft’s engines. It is possible to reverse the aircraft by pushing it with a tractor, from its parking position. This is commonly referred to as a ‘pushback’. Documents U.S. Patent describe, for example, systems used to pull aircraft along the ground. Nos. Nos. The tractor can be controlled remotely or by a pilot seated on the appliance. “The tractor is usually connected to the nose landing equipment of the aircraft to move it.

The nose landing gear was not designed to perform this type of operation. Landing gear fatigue can be caused by the stresses created when moving the aircraft. This increases the likelihood of nose landing gear failure. The nose landing gear can be reinforced in order to reduce these risks. However, this would increase the weight of aircraft, and consequently the fuel consumption during flight. The cost to reinforce or replace the nose landing gear would be prohibitive.

The invention aims to make it easier for aircraft to move along the ground by using their engines.

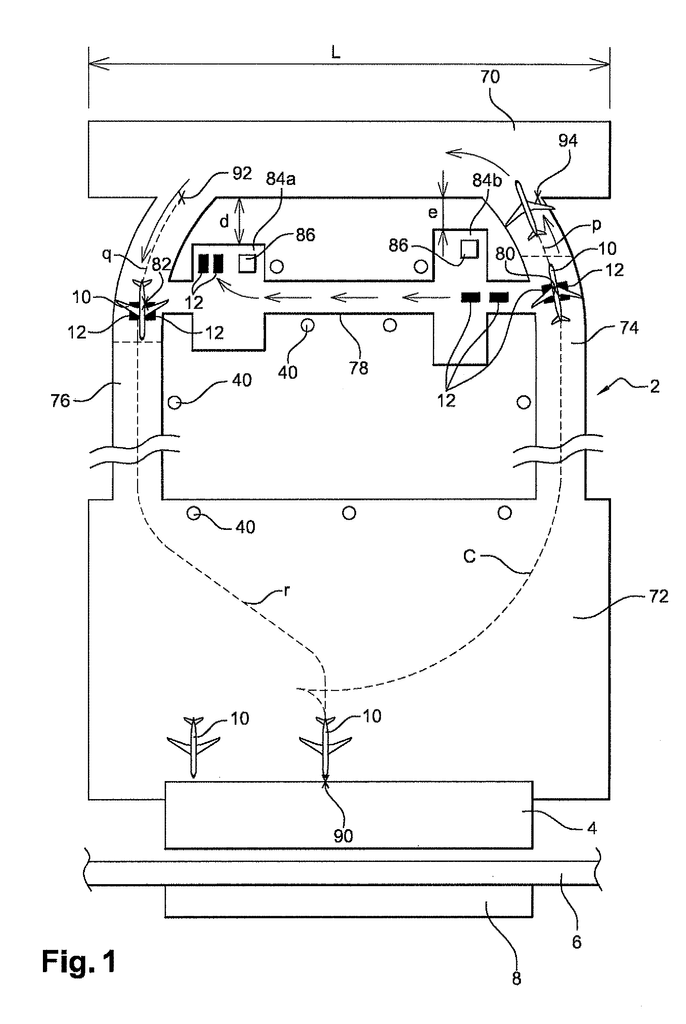

The invention therefore provides a method of moving an aircraft along the ground using at least two separate appliances that are connected to the aircraft in a way that they can be moved independently or by other appliances.

Advantageously one part of an aircraft, like a landing-gear, can be moved forward using one of these appliances and another part, like a landing-gear, can be moved backwards by another appliance.

The aircraft should be moved using at least one other landing gear than the nose landing wheel.

The main landing gears are generally stronger than nose landing gear. The nose landing gear is not put under too much pressure, and it does not need to be reinforced to allow it to move.

Advantageously the speed of one appliance is different than that of another or of any of the other appliances.

This allows the aircraft to move along the ground while turning.

Preferably at least one appliance is controlled based on at least a datum related to a position or movement of another appliance, or at least of one of the others appliances.

It is advantageous to control the movement of an aircraft using the appliances from within the aircraft. Preferably, this can be done from the cockpit.

Traditional movements involve three people: the controller and the pilot of the aircraft, as well as the driver of the tractor. Communication between three persons can lead to misunderstandings that could put safety at risk. The procedures state that even if the aircraft is being maneuvered using an apparatus on the ground, the pilot is still responsible. “If the appliances can be controlled by the pilot from within the aircraft, aircraft movements will be more efficient.

The aircraft can be braked by using one or more of the devices.

At least one of the appliances is advantageously:

The appliance is controlled by the position or movement of the front wheels. The pilot can plan to simply move the wheel on the aircraft for the appliances to interpret and move the plane in the correct direction.

At least one of the appliances is advantageously:

The control of the operation of coupling the appliances to an aircraft is automated to simplify and accelerate the handling of the plane after landing.

At least one of these appliances should be preferred:

Click here to view the patent on Google Patents.