Invented by Bharrat; Shaun Jaikarran, Chaudhary; Sanchit, Nayak; Subhransu S., Subramanian; Rajangam, Chand; Subhashis, Ouellet; André, Ramachandran; Gopannan

Testing new network equipment is hard. It takes a lot of time. It costs a lot of money. If you do it the old way, you need lots of people. They make mistakes. They miss things. That means some problems are not caught before new products are shipped. When things go wrong, customers get upset. This is a big problem for everyone who builds, sells, or uses network gear, like Session Border Controllers (SBCs) and other SIP call processing devices.

What if we could test new software and hardware better, faster, and with less human effort? What if we could use real customer data to make sure our tests are just like real life? That is exactly what the patent application we are exploring today is about. It describes a way to use learning-based automation to test SIP call processing entities in a lab, using real-world data and smart configuration copying. Let’s break down how this works, why it matters, and what makes it different from past approaches.

Background and Market Context

In today’s telecom world, change is fast. New features, security updates, and bug fixes are rolled out all the time. Network operators and equipment vendors have to be sure that these changes do not break anything. But testing is slow. Sometimes it takes a year or more just to test and roll out a new software version. Why? Because most testing is still done by hand. People write test plans, set up test labs, create fake calls, and check results. This takes a lot of effort and still misses many real problems.

The main device in the spotlight here is the Session Border Controller, or SBC. SBCs are the gatekeepers of modern voice and video over IP (VoIP) networks. They connect different networks, make sure calls are secure, and help with routing calls. If an SBC does not work right after an update, lots of customers could lose service. So testing these devices is very important.

But there is a big gap between testing in a lab and what happens in the real world. In the lab, the setup is often old or not up to date. The call flows are made up by test engineers, not captured from actual traffic. Many types of calls and edge cases are missed. As a result, some bugs only show up after the software is deployed, causing outages or trouble for customers. This makes customers wary of upgrading, which means they miss out on new features and important security updates.

Another issue is cost. Manual test planning, setup, and execution eats up a huge part of the research and development (R&D) budget. Every hour a skilled engineer spends writing or running tests is an hour not spent building new features. This slows down innovation.

The telecom industry has tried to fix this in a few ways. Some companies use record-and-playback tools, which capture and replay signaling messages. Others use traffic generators or write scripts to mimic real traffic. But these tools still need lots of setup, and they do not keep up with changing customer networks or call flows. They also do not catch all the subtle problems that can happen when real-world configurations change.

The market needs something better: a way to copy real network behavior and setups into a lab, keep the lab up to date, and let automated systems run tests over and over, quickly, with very little human work. That way, equipment makers can ship new versions faster and with more confidence. Customers can upgrade quickly, knowing their specific use cases are covered. And everyone saves money.

Scientific Rationale and Prior Art

To understand why the new approach in this patent is important, let’s look at what came before and why past methods fall short.

Traditional SIP testing often involves creating test plans by hand. Engineers try to guess what kind of calls and situations the device will handle. They build test cases for the most common flows, plus a few edge cases. But customer networks are complex, and traffic patterns change over time. New call flows appear, old ones disappear, and configurations evolve. The result is that manual test plans can never really keep up. Many real-world scenarios go untested.

Some testing systems try to use captured traffic, like PCAP (packet capture) files or call traces, to replay real calls in the lab. This is a good idea, but it has some problems. First, the lab SBC or device under test is often not set up exactly like the one in production. IP addresses, network interfaces, and connections to other devices (like DNS servers or policy servers) are different. If you replay a call using production addresses in the lab, the test will fail or go to the wrong place.

Other tools try to help by letting you import configuration files. But they still need a lot of manual tweaking. Every time a customer’s network changes, someone has to update the lab manually. If this does not happen, the lab drifts further from reality, and tests become less useful.

On the call flow side, there have been some attempts to “learn” traffic patterns by sampling calls and trying to model typical flows. But most of these models focus on traffic volume, not the details of signaling messages or the exact setup of the network devices. They might tell you that there are a lot of calls at 9am, but not what headers, codecs, or policies are being used.

Other tools automate test execution, but not creation. That is, they can run scripts quickly, but someone still has to write and maintain the scripts. If the network changes or call flows evolve, the scripts become stale.

In summary, the prior art has tried to make SIP device testing easier, but none has fully automated the process of (a) copying real-world configurations into the lab, (b) learning real call flows at a detailed level, (c) updating the lab setup as the production network changes, and (d) generating and executing test cases that are truly representative of what happens in the field. This patent aims to address all of these gaps in a unified, automated way.

Invention Description and Key Innovations

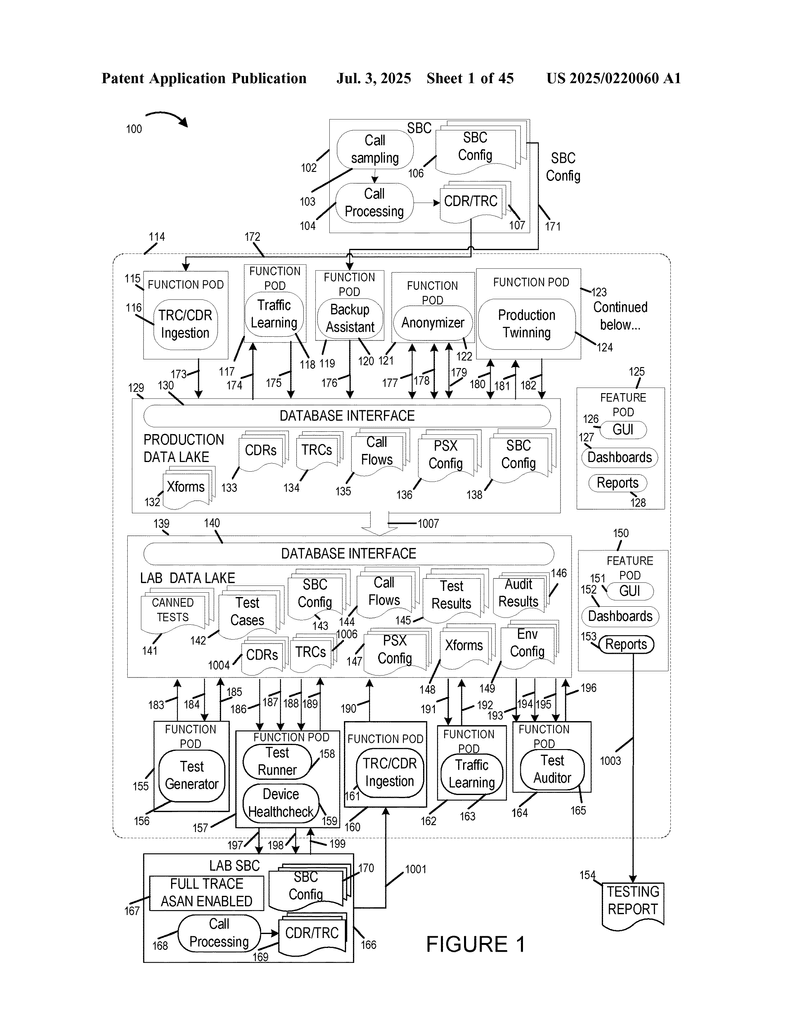

This invention is all about building a smart, learning-based, automated testing system for SIP call processing devices, like SBCs. The goal is simple: make sure the device-under-test in the lab behaves just like the real one in the field, using real traffic patterns and network setups, with very little human intervention. Let’s walk through how it works and what makes it unique.

Learning From the Real World

The system starts by capturing real call data from a production SBC (the device that is already deployed and handling real calls). It uses built-in sampling features to pick a small percentage of calls—maybe 0.5%—to record in detail. For each sampled call, it saves both the call detail record (CDR) and a trace record (which includes all the SIP messages, headers, and sometimes media info). Over time, this builds up a rich history of the actual call flows the customer’s network is handling. This step is automatic and continuous, so the system always has up-to-date data.

Why sample? Because capturing every call would create too much data and be hard to manage. By sampling, the system can still learn the important patterns and rare cases, given enough time.

Building a Traffic Model

Next, the system analyzes the captured data. It looks at the CDRs and trace records and extracts detailed features about each call flow. This includes things like which SIP messages were exchanged, which headers and parameters were present, which codecs were used, and what routing decisions were made. It builds a model of “unique” call flows by removing duplicates, so each test case represents a real, but distinct, scenario from the production network.

This model is not just about counting calls—it’s about capturing the structure and details of the signaling. For example, it notes the order of messages, the fields in each header, and the parameters that might affect call setup or tear-down.

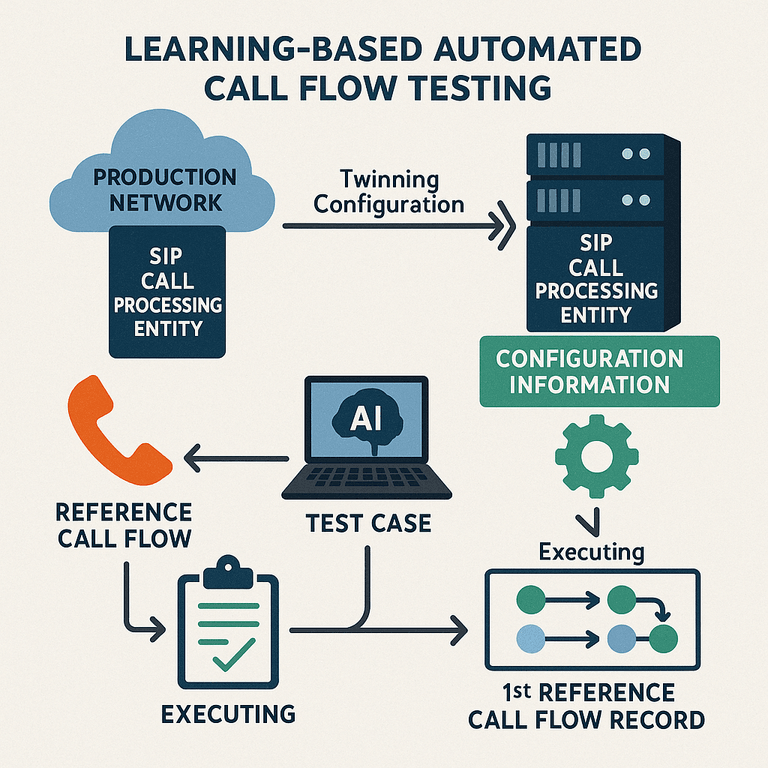

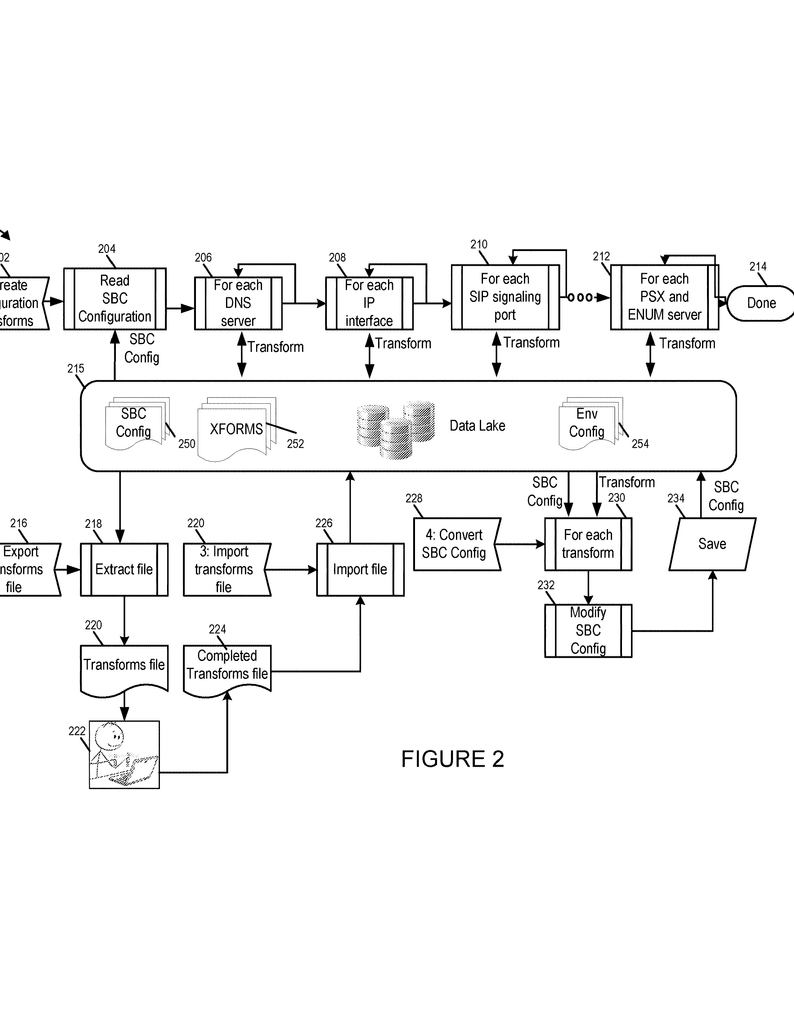

Twinning the Configuration

A big challenge in using production call data is that the lab is never set up exactly the same as the real network. IP addresses are different. The DNS server in the lab is not the same as the one in the field. The SBC might have different interfaces or be connected to different devices.

This invention solves that with an automated “twinning” process. It downloads the full configuration from the production SBC, then automatically creates a set of “transforms” to map all the production addresses, ports, and device references to their lab equivalents. For example, it might change the production DNS server IP to the lab DNS IP, or map a public interface to a private one in the lab.

These transforms are kept in a structured way, so they can be reused and updated as the network changes. If the production network adds a new device or changes an IP, the transform is updated, and the lab configuration is regenerated automatically.

Automated Test Case Generation

With the call flow model and the twinned configuration in place, the system can now generate test cases automatically. For each unique call flow, it creates scripts (using tools like SIPp) that will send the right SIP messages to the device-under-test, using the correct lab addresses and network setup. It can also simulate or emulate other devices (like SIP endpoints, DNS servers, or policy servers) as needed.

Each test case is linked back to its original reference call flow, so when the test runs, the system knows exactly what to expect in terms of messages, headers, codecs, and so on.

Automated Execution and Auditing

The next step is execution. The system loads the correct configuration onto the lab SBC, runs the test scripts, and captures the results. While the tests run, the system can also watch for health issues, like memory errors or crashes (using tools like Address Sanitizer).

After each test, the system compares the actual call flow in the lab with the reference call flow from production. If there are mismatches—like missing messages, wrong headers, or out-of-order events—the test is flagged as failed. The system can also compare details in the CDRs, like disconnect reasons or selected codecs. If the routing is non-deterministic (i.e., sometimes the production device picks one route, sometimes another), the system can retry the test multiple times to account for random differences.

All results are saved and can be shown in reports or dashboards. Engineers and testers can see exactly which features passed or failed and drill down into the details if needed. The whole process—from data capture to configuration, test creation, execution, and audit—is automated and repeatable.

Continuous Updates and Customization

One of the most powerful features of this approach is that it is continuous. As the production network changes—new devices, new call flows, new configurations—the system keeps sampling and learning. The lab setup is always up-to-date, and the test cases always reflect the latest reality.

The process can also be customized. If a customer wants to focus on certain types of calls or specific network features, filters can be applied. The system is flexible enough to handle both hardware and virtual SBCs, and can be deployed in cloud environments using modern orchestration (like Kubernetes).

Key Differences from Prior Art

What makes this invention stand out? Here are the main innovations:

- It automatically learns and models real call flows, using continuous in-production sampling, not just static test plans.

- It automates the process of creating a lab configuration that exactly matches production, with all addresses and device references properly mapped.

- It generates test scripts for each unique call flow, ensuring full coverage of real-world scenarios.

- It keeps everything up to date as the production network changes, so the lab is never out of sync.

- It automates the audit of test results, comparing detailed signaling features and CDRs, not just call completion.

- It supports emulation of external devices and handling of non-deterministic routing or policy behavior.

In short, this invention turns SIP device testing from a slow, manual, error-prone process into an automated, learning, and highly accurate system that reflects what really happens in the field.

Conclusion

Testing SIP call processing equipment like SBCs has always been a challenge. Manual methods are slow, expensive, and often miss real-world problems. The approach described in this patent changes the game. By learning from real customer traffic, automatically twinning configurations, and generating detailed, up-to-date test cases, it brings lab testing much closer to reality.

With this system, vendors and operators can roll out new software and hardware faster, with greater confidence, and at lower cost. Customers can upgrade more often, get new features sooner, and be sure that their unique network scenarios are truly tested. As telecom networks continue to evolve, tools like this will be essential for keeping pace with change, reducing risk, and delivering high-quality services.

If you are involved in SIP device development, testing, or operations, understanding and adopting learning-based automated testing could be the key to faster releases, fewer outages, and happier customers. The future of telecom QA is smart, automated, and driven by real data—and it starts here.

Click here https://ppubs.uspto.gov/pubwebapp/ and search 20250220060.